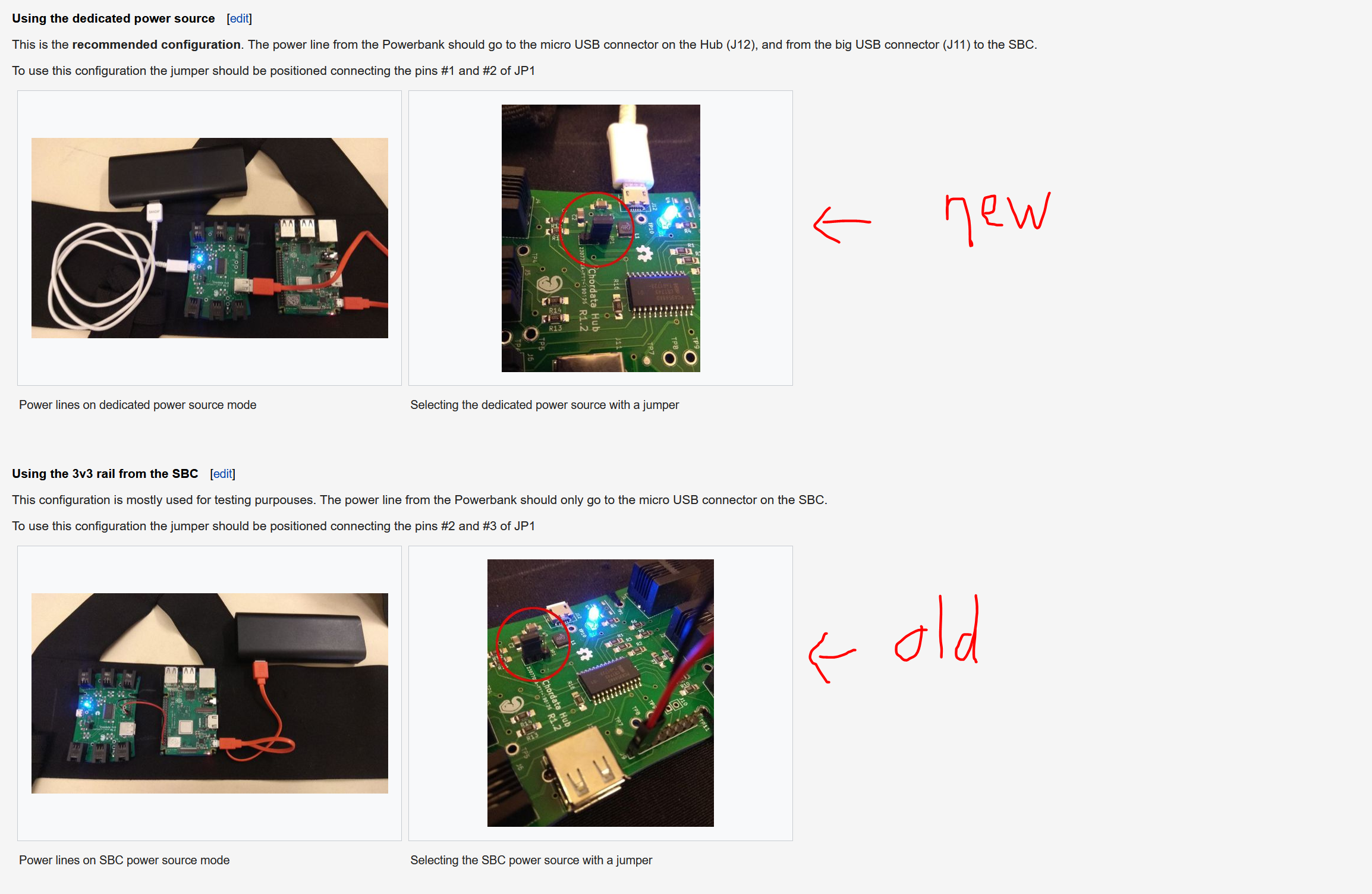

I should also mention, in case I haven't before, that the indicator light on the Hub isn't on. This is true of the KCeptors, but with the hub, I have seen it flicker on. At the time, I was fiddling with the old vs new power settings. The "old" setting being the one where you connect the power to the Pi, and then use jumpers from 6 or so of those pins to the first 6 pins on the Hub. It didn't consistently stay on that way either, but it did light up for a bit, and then I bumped it and the light went back off.

Normally I'd consider that a problem with powering things, except the "new" power configuration uses the USBs instead of those pins, plus the jumper on the three pin is in the other position. Plus the Pi is getting power, it's just the indicator light that isn't lighting up. So I'm not sure what to make of it, whether power is getting to certain sections of the board and not others, or whether I'm getting a little power everywhere, but not necessarily a lot of power. Now I assume the test you gave me to do is a test of whether my chip is working or not. But I just want to mention that it could be a power problem.